Knowledge about furnaces

We have collected a vast base of knowledge during the years

Design

Our furnaces are designed with the best materials and components in the market to fulfil the specified performance.

The process in the design incorporates a systematic discussion with the customer to ensure the requirements for the furnace. The process in the design incorporates a systematic discussion with the customer to ensure the requirements for the furnace. Questions of importance in the design process:

→ Temperature level → Temperature profile → Rate of heating up and cooling down

Normally the requirements are covered by a standard furnace which probably is the most economical solution. Our vast experience in furnace design will assist our customers to make an optimal choice of furnace.

Certain of our designs are proprietary designs and cannot be disclosed. This is normally covered in an agreement decided at contract signing.

Different techniques depending on temperature

The technology used is primarily decided by the temperature level in the furnace chamber. When we are using oxidizing atmosphere metallic elements are used for temperatures up to 1300 OC. These elements are normally applied as wires mounted on ceramic support bars or embedded in the insulation.

When the operating temperatures reach up to a maximum of 1550 OC silicon carbide elements are used. They are applied as rods mounted horizontally or vertically.

Ceramic molybdenum-disilicide elements are used when the furnace temperature are up to 1800 OC. These elements are hairpin shaped and are mounted vertically hanging through the roof of the furnace alongside the furnace walls.

For furnaces operating up to 2100 OC the only elements that can operate in oxidizing atmosphere are Zirconium dioxide elements. They require very specific design solutions. For these furnaces only smaller chambers can be built.

In even higher temperatures graphite elements are used in vacuum or protective gas atmospheres.

Temperature uniformity

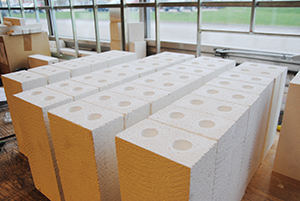

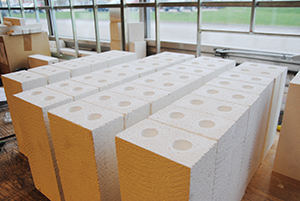

In order to obtain good temperature uniformity the elements must be situated in the chamber depending on how the insulation is designed. We are normally using ceramic fibres or high temperature bricks as the hot phase. A combination of lower grade insulation materials will then assure good operating economy, high temperature uniformity with a long life.

Controlling

The control of the furnace temperature is important and normally thyristor control is used. Also program for taking the furnace up to temperature and for cooling down is often included in the temperature controller. Many customers also require data logging of temperatures and careful process control which is performed by computer control.